Introduction

Metal sculptures represent one of the most dynamic forms of art in architecture and design. From monumental outdoor installations in plazas and parks to refined decorative works in hotels, villas, and commercial interiors, these pieces bring together artistic creativity, engineering precision, and advanced material science.

At NEXTOP, our expertise in Architectural Metal Works and Surface Finishes allows us to create custom sculptures that are not only visually striking but also engineered to endure. In this guide, we’ll take you through every step of the metal sculpting process, showing how raw metal becomes a finished piece of art.

Step 1: Concept & Design Development

Every sculpture begins with a conceptual vision. This can be inspired by:

- Nature (waves, mountains, animals)

- Geometric forms (minimalist patterns, abstract shapes)

- Cultural heritage (symbols, motifs, historical references)

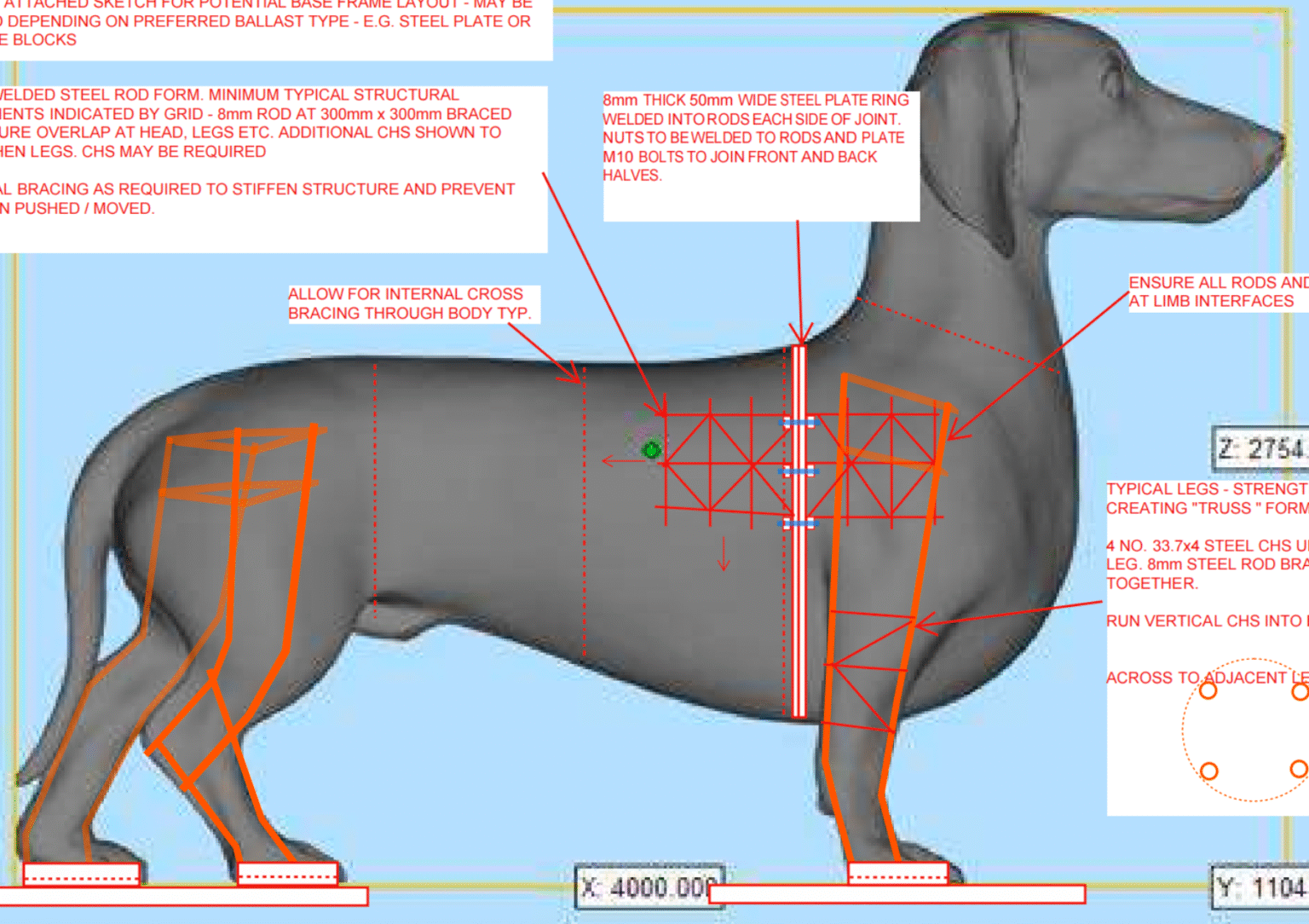

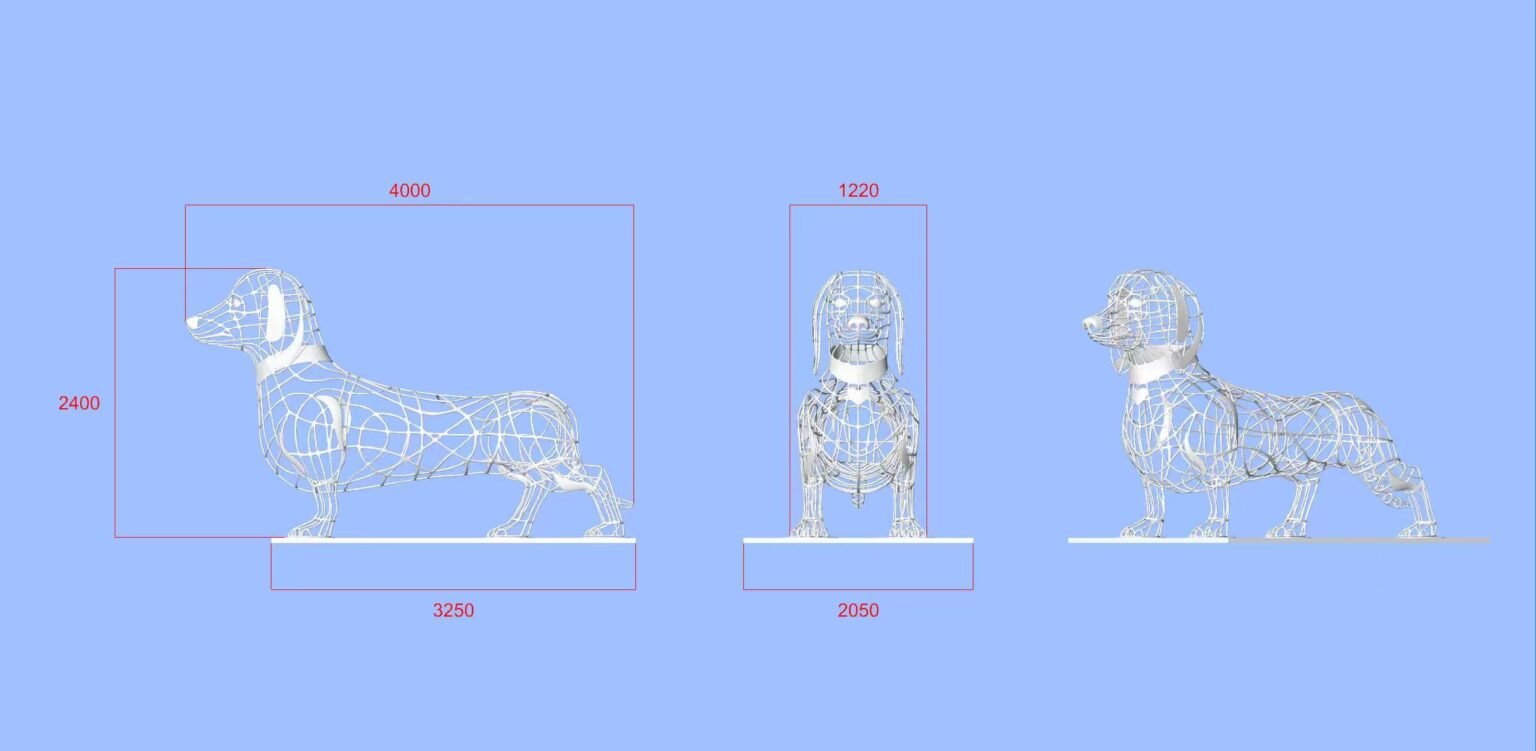

Our design team works closely with architects, designers, and clients to create sketches and 3D models. Using CAD and 3D visualization tools, we simulate how the sculpture will look in its intended space — whether it’s a hotel lobby, a luxury villa garden, or a city plaza.

Step 2: Material Selection

Choosing the right metal is critical. Each material affects the sculpture’s aesthetics, structural integrity, and long-term durability.

- Stainless Steel (304/316): Excellent corrosion resistance, ideal for outdoor sculptures, available in mirror polish or brushed finish.

- Aluminum: Lightweight, versatile, often used for large-scale works where weight reduction matters.

- Bronze & Copper: Traditional, warm tones, often used for cultural or classical sculptures; develops a natural patina over time.

- Corten Steel (Weathering Steel): Creates a rust-like surface that acts as a protective layer, often used in modern outdoor art.

Step 3: Fabrication Techniques

Fabrication transforms raw materials into tangible forms. This stage combines engineering precision with artisanal craftsmanship.

Cutting

- CNC Laser Cutting: Creates highly detailed patterns and shapes.

- Waterjet Cutting: Allows smooth, heat-free cutting for delicate designs.

Shaping & Forming

- Press Brakes: Bend and curve metal sheets.

- Rolling Machines: Create cylindrical or curved components.

Welding & Assembly

- TIG/MIG Welding ensures strong, seamless joints.

- Internal frames or support structures are added for large sculptures.

- Every weld is ground and smoothed to prepare for finishing.

Step 4: Surface Finishing

The finish defines both appearance and performance. NEXTOP provides a wide range of options:

- Brushed / Satin Finish: Subtle, modern texture, reduces glare.

- Mirror Polished Stainless Steel: Reflective, eye-catching, often used in iconic public art.

- Powder Coating: Durable, available in many colors, adds protection against UV and weather.

- PVD Coating: Premium gold, bronze, or black finishes with high durability.

- Vibration Finish: Unique texture, often used for artistic panels.

These treatments enhance visual appeal while protecting against corrosion, scratches, and environmental damage.

Step 5: Quality Control

Before installation, every sculpture undergoes strict inspection:

- Dimensional accuracy checks

- Welding integrity and surface smoothness

- Finish consistency (polish, coating, or patina)

- Structural load testing for large outdoor pieces

NEXTOP’s quality assurance team ensures each project meets international standards and client specifications.

Step 6: Delivery & Installation

- Large-scale sculptures require logistics planning:

- Secure crating and protective packaging

- Transport via trucks or containers

- On-site assembly for oversized works

During installation, anchoring systems are used for stability (especially outdoors). The foundation may involve reinforced concrete bases or steel anchoring plates.

Step 7: Maintenance & Longevity

Metal sculptures are built to last, but proper maintenance extends their lifespan:

- Indoor Sculptures: Routine dusting and occasional polishing.

- Outdoor Sculptures: Regular cleaning, protective coatings, weld inspections, touch-ups for finishes.

- Bronze / Copper Works: Allow natural patina or apply clear coatings for preservation.

NEXTOP offers post-sales service to help clients maintain their sculptures over decades.

Why Choose NEXTOP for Metal Sculptures

- Expertise: Decades of experience in architectural metal fabrication.

- Customization: Tailor-made designs, from abstract art to cultural landmarks.

- Global Projects: Trusted partner for hotels, villas, shopping malls, and public spaces worldwide.

- Durability: Advanced finishes and materials that withstand both time and climate.

👉 If you’re looking for custom Architectural Metal Sculptures for your next project, NEXTOP is your trusted partner.